OVERVIEW OF BARITE

Barite, chemically known as barium sulfate (BaSO4), is a high-density non-metallic mineral. Barite crystals belong to the orthorhombic (orthorhombic) crystal system, often appearing as thick plate or columnar crystals, mostly dense block or plate-like, granular aggregates. Pure barite is white and shiny, but due to the influence of impurities and mixed materials, it is often gray, light red, light yellow, etc. Barite with good crystallization can also appear as transparent crystals.

Barite is mainly produced in low-temperature hydrothermal veins, often coexisting with quartz, calcite, fluorite, galena, pyrite, dolomite, chalcopyrite and sphalerite. It can also be produced in limestone and sandstone in the form of nodules or cements.

APPLICATIONS OF BARITE

Zenith has developed and produced new products such as vertical roller mill, European grinding mill and ultrafine powder grinding mill, and offers integrated grinding solutions for high-quality barite powder that meets the needs of different industries.

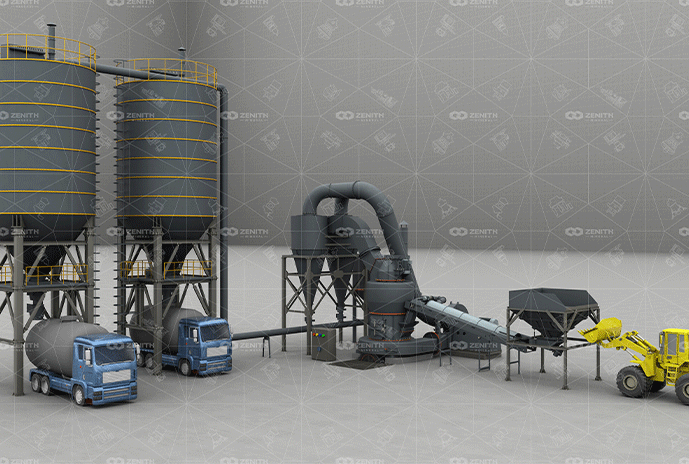

THE PROCESS OF GRINDING SYSTEM

Grinding

stage

Grinding

stage

Material of suitable size is fed into the main machine for grinding, and the fine powder after grinding is sent to the analyzer for grading under the action of the air flow of the fan, so that the fine powder with qualified fineness can enter the collecting stage.

Collecting

Stage

Collecting

Stage

The dust gas enters the cyclone collector through the outlet pipe. Under the action of centrifugal force, most of the finished fine powder is separated. Redundant gas is discharged and sent to pulse dust collector. Then it becomes clean gas. Fine powder collected by cloth bags is transported to the conveying stage through screw conveyor.

Conveying

Stage

Conveying

Stage

The finished powder collected by dust collector and cyclone collector is sent by screw conveyor to the next process or into finished product tank.

CORE GRINDING EQUIPMENT

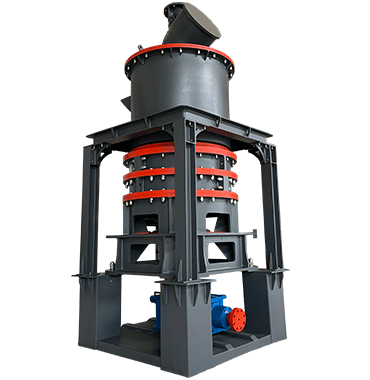

LM VERTICAL ROLLER MILL

Capacity: 10-170T/H

Fineness: 0.84-0.037mm

Performance Advantages:

New grinding device

Automated electronic control system

Drying and grinding two-in-one

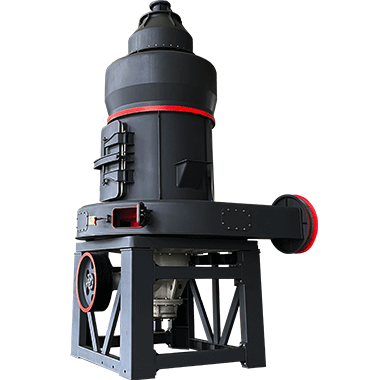

MTW EUROPEAN TRAPEZIUM MILL

Capacity: 3-60T/H

Fineness: 1.6-0.045mm

Performance Advantages:

Patented product

Thin oil lubrication system

Energy saving, environmentally friendly

LUM ULTRAFINE VERTICAL MILL

Capacity: 3-15T/H

Fineness: 325-2500mesh

Performance Advantages:

Multi-head powder selection, economical

Higher yield and better quality

Safe and reliable, stable operation

XZM ULTRAFINE GRINDING MILL

Capacity: 500-25000KGPH

Fineness: 325-3250mesh

Performance Advantages:

Stable, reliable, environmentally friendly

High efficiency and low loss

High fineness

CUSTOMER CASES

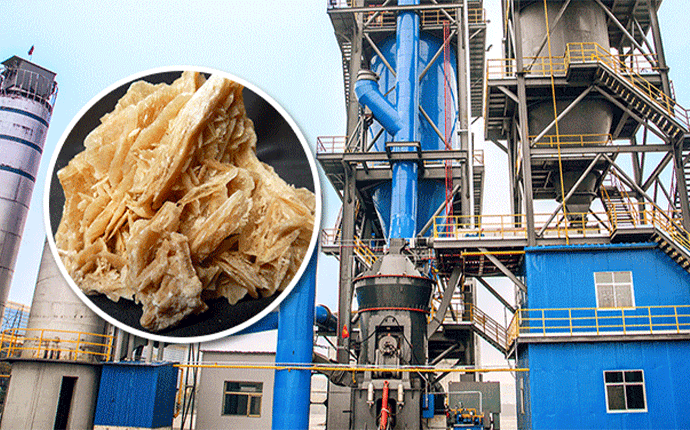

Annual 300 Kilotons Barite Powder Production Line

Fineness: 250mesh

Application: Drilling mud weighting agent

Equipment: LM vertical roller mill

Annual 100 Kilotons Barite Grinding Plant

Fineness: 200mesh

Application: Paint Filler

Equipment: MTW European trapezium mill

MORE CASES FOR YOUR REFERENCE

PURSUING THE ZENITH TECHNOLOGY AND QUALITY

Get Solution & Price Right Now!

If you would like to receive personalized solutions and a free quote, kindly provide your information below.

Chat Online

Chat Online