INDUSTRY OVERVIEW

The global economic landscape continues to evolve. The Philippines, an economic growth engine in Southeast Asia, is advancing urbanization and infrastructure projects at an unprecedented pace, which has opened up unprecedented development opportunities for the local building materials industry.

Nowadays, local consumers have increasingly diverse requirements for building materials. They not only value quality, but also pay more attention to environmental attributes and innovative designs. This trend has directly driven the growth in demand for AAC blocks – a type of block that combines four major advantages: light weight, high strength, thermal insulation, and sound insulation, perfectly meeting the new market demands.

In the production process of AAC blocks, every step – from raw material grinding and material mixing to casting and final curing – affects the final quality. Among these, the quality of quicklime powder and pulverized coal plays a decisive role. The fineness and purity of quicklime powder are directly related to the strength and thermal insulation effect of the blocks, while the quality of pulverized coal significantly influences the combustion efficiency during production. It is evident that selecting high-efficiency grinding equipment has become a core link in improving the quality of AAC block products and accelerating the production pace.

ENTERPRISE'S NEED TO BREAK THROUGH THE BOTTLENECK

Currently, the local building materials industry in the Philippines is facing three core

dilemmas, which have severely restricted its market competitiveness. First is the shortage

of talents, second is the backwardness of technology, and finally is the uneven quality of

products. The combination of these three pain points makes it difficult for the local

building materials industry to keep up with the growing market demand for high-quality

building materials. Especially against the backdrop of accelerated urbanization and expanded

infrastructure projects, the gap between market supply and demand continues to widen.

As a key player in the local industry, the client enterprise faces both development

opportunities brought by strong market demand and competitive pressures from industry

dilemmas. On one hand, the demand for high-quality, lightweight, and eco-friendly building

materials like AAC blocks has surged in local infrastructure, real estate, and other

sectors, presenting enormous market potential. On the other hand, bottlenecks in its own

production processes—such as low efficiency in the grinding stage and insufficient precision

in raw material grinding—directly lead to long production cycles and poor product quality

stability. This will help the enterprise quickly break through bottlenecks in the fierce

market competition, seize the first-mover advantage in the high-quality building materials

market, and consolidate and expand its market share in the industry.

SHANGHAI ZENITH CUSTOMIZED GRINDING SOLUTION

In the field of grinding equipment and system solutions, Shanghai Zenith has established unique advantages in the fierce market competition, relying on over 30 years of technical accumulation and continuous innovation capabilities, and successfully gained recognition from Philippine customers. To address the customer's core needs for AAC block production, we did not provide standardized products, but tailored a set of grinding production system solutions that integrate "high efficiency and stability" with "environmental friendliness".

To ensure the solution perfectly fits the customer’s actual scenario, the professional team of Shanghai Zenith conducted multiple rounds of on-site surveys in the early stage, deeply analyzing the local production environment, raw material characteristics, and site conditions in the Philippines.

It can be said that this solution not only addresses the customer’s current production pain points but also provides reliable hardware support for its long-term capacity expansion and product competitiveness improvement, truly realizing the cooperative value of "one-time investment, long-term benefits".

-

Raw Material Testing

-

Technical Communication

-

Solution Development

-

Equipment Manufacturing

-

Installation and Commissioning

-

Operation Guidance

-

Technical Q&A

-

Spare Parts Supply

EQUIPMENT SELECTION

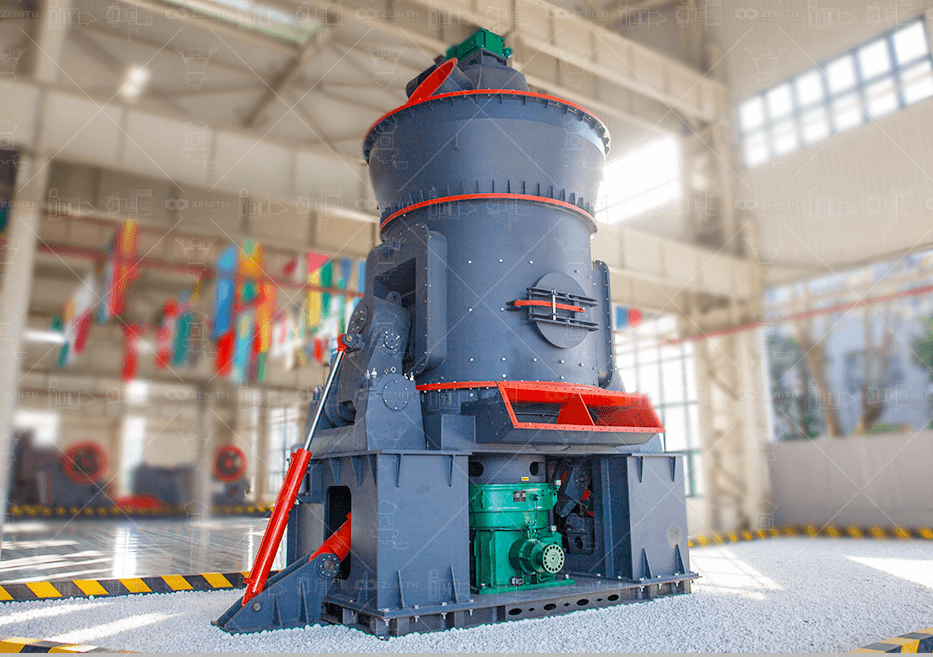

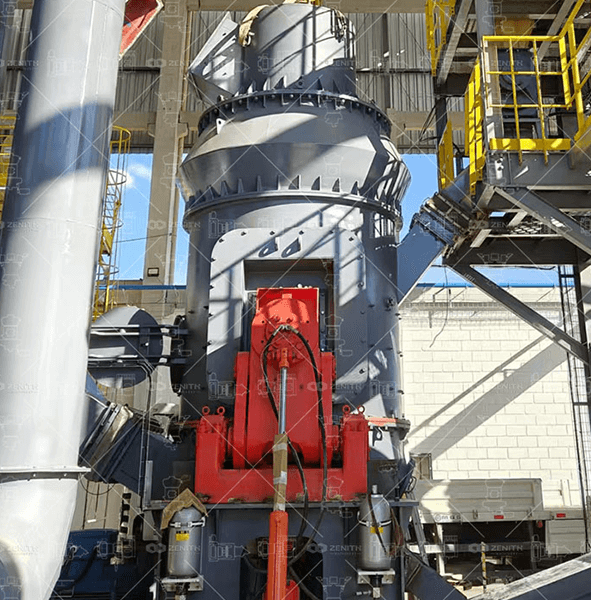

Based on the different characteristics of pulverized coal and quicklime powder, Shanghai Zenith has selected the LM Vertical Roller Grinding Mill as the core equipment by leveraging its rich experience and advanced technology. This equipment integrates advanced grinding technology and design, enabling efficient refinement of pulverized coal and quicklime powder while ensuring excellent and stable quality of finished products.

Multi-Function in One Machine

Multi-Function in One Machine

Wide Application Range

Wide Application Range

Excellent Finished Product Quality

Excellent Finished Product Quality

-

Low Investment Cost

Low Investment Cost

-

Low Operating Cost

Low Operating Cost

-

Strong Drying Capacity

Strong Drying Capacity

-

Easy Operation & Reliable Operation

Easy Operation & Reliable Operation

-

Excellent Finished Product Quality

Excellent Finished Product Quality

-

Green & Environmentally Friendly

Green & Environmentally Friendly

EQUIPMENT RELATED CASES

Get Solution & Price Right Now!

If you would like to receive personalized solutions and a free quote, kindly provide your information below.