INDUSTRY BACKGROUND

Carbon refers to carbon and graphite materials, which are non-metallic solid materials mainly composed of carbon elements. Carbon products are resistant to high temperatures, corrosion, thermal shock and good electrical conductivity, and are irreplaceable materials in many special fields.

At the same time, the raw materials used in the production of carbon products are the residues in the production process of petrochemical and coal chemical industries, namely petroleum coke and asphalt coke, which are secondary utilization of energy and belong to the circular economy industry.

Applications of Carbon Raw Materials

With the rapid development of aviation, military, electronics and other industries, and the in-depth research of carbon materials such as nanocarbon and graphene, the use of carbon products will become more and more extensive.

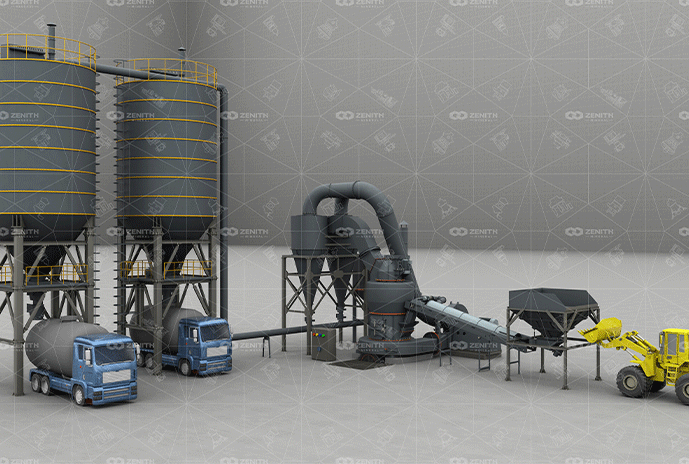

THE PROCESS OF GRINDING SYSTEM

Grinding

stage

Grinding

stage

Material of suitable size is fed into the main machine for grinding, and the fine powder after grinding is sent to the analyzer for grading under the action of the air flow of the fan, so that the fine powder with qualified fineness can enter the collecting stage.

Collecting

Stage

Collecting

Stage

The dust gas enters the cyclone collector through the outlet pipe. Under the action of centrifugal force, most of the finished fine powder is separated. Redundant gas is discharged and sent to pulse dust collector. Then it becomes clean gas. Fine powder collected by cloth bags is transported to the conveying stage through screw conveyor.

Conveying

Stage

Conveying

Stage

The finished powder collected by dust collector and cyclone collector is sent by screw conveyor to the next process or into finished product tank.

CORE GRINDING EQUIPMENT

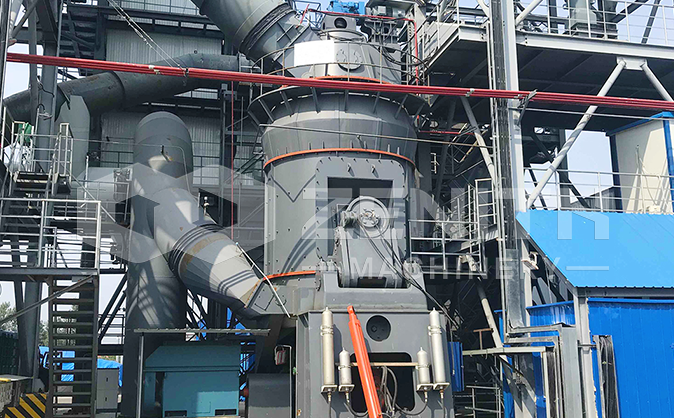

LM VERTICAL ROLLER MILL

Capacity: 10-170T/H

Fineness: 0.84-0.037mm

Performance Advantages:

New grinding device

Automated electronic control system

Drying and grinding two-in-one

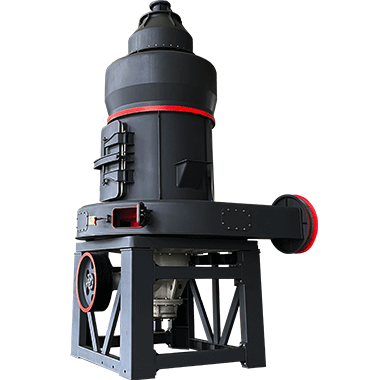

MTW EUROPEAN TRAPEZIUM MILL

Capacity: 3-60T/H

Fineness: 1.6-0.045mm

Performance Advantages:

Patented product

Thin oil lubrication system

Energy saving, environmentally friendly

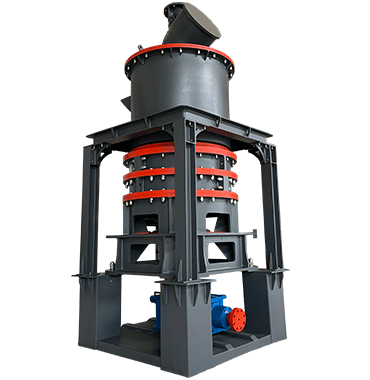

LUM ULTRAFINE VERTICAL MILL

Capacity: 3-15T/H

Fineness: 325-2500mesh

Performance Advantages:

Multi-head powder selection, economical

Higher yield and better quality

Safe and reliable, stable operation

XZM ULTRAFINE GRINDING MILL

Capacity: 500-25000KGPH

Fineness: 325-3250mesh

Performance Advantages:

Stable, reliable, environmentally friendly

High efficiency and low loss

High fineness

CUSTOMER CASES

Carbon Anode Materials for Aluminium Electrolysis Project

Material: calcined petroleum coke

Fineness: 200mesh

Equipment: LM vertical roller mill

Annual 200 Kilotons Graphite Electrode Project

Material: calcined petroleum coke

Fineness: 200mesh

Equipment: MTW European trapezium mill

MORE CASES FOR YOUR REFERENCE

PURSUING THE ZENITH TECHNOLOGY AND QUALITY

Get Solution & Price Right Now!

If you would like to receive personalized solutions and a free quote, kindly provide your information below.

Chat Online

Chat Online