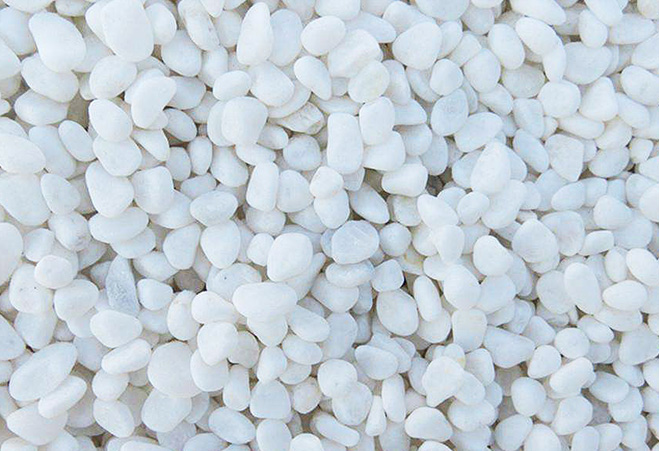

OVERVIEW OF DOLOMITE

Dolomite is an important calcium-magnesium resource, primarily composed of magnesite and

calcite, with minor amounts of clay minerals and chert, and occasionally containing gypsum,

celestite, barite, pyrite, organic matter, etc.

Abundant in reserves and distributed across all provinces, dolomite boasts proven deposits

sufficient to meet the demands of economic development. Characterized by high contents of

MgO and CaO, together with higher purity and fewer impurities, dolomite serves as a

high-quality raw material for industries such as metallurgy, chemical engineering, building

materials, rubber, and refractories.

As a non-metallic mineral resource with considerable economic value and potential for

diversified development and utilization, the fine processing, efficient and rational

utilization of dolomite are of vital importance.

APPLICATION OF DOLOMITE

Dolomite can serve as a refractory inner lining for converters in steelmaking, a slag-forming agent,

a raw material for cement production, a flux in glass manufacturing, and a key material for

ceramics, fertilizers, construction and decorative stones, coatings, pesticides, pharmaceuticals,

and other applications.

It is also widely applicable in sectors such as building materials, ceramics, glass and

refractories, chemicals, as well as agriculture, environmental protection, and energy conservation.

After being processed into powder, dolomite boasts a wide range of applications. It can be used to

produce new-type refractory materials and smelt magnesium metal, boosting industrial production; it

can also improve soil pH levels to serve agriculture and forestry, and is applicable to scenarios

such as coatings, putty powder, papermaking and PE manufacturing, thus emerging as a high-quality

raw material across multiple fields.

New-Type Refractory

Materials

Fine-ground dolomite can be used in new-type refractory materials.

Magnesium Industry

Pulverized dolomite is applicable to magnesium metal smelting.

Building Materials

Dolomite can be used to manufacture magnesia cement and coatings.

Agriculture and Forestry

Dolomite powder is effective in regulating soil pH levels.

DEEP GRINDING PROCESSING OF DOLOMITE POWDER

To meet the requirements for dolomite fineness across diverse fields, Zenith has developed a full range of dolomite milling equipment, mainly consisting of fine powder mills (80–400 mesh) including the LM Vertical Mill and MTW European Trapezium Mill, as well as ultrafine powder mills (400–3250 mesh) such as the LUM Ultrafine Vertical Mill and XZM Ultrafine Mill.

-

MTW Grinding Mill

MTW Grinding Mill

-

LM Vertical Mill

LM Vertical Mill

-

LUM Vertical Mill

LUM Vertical Mill

-

XZM Ultrafine Mill

XZM Ultrafine Mill

EQUIPMENT SELECTION AND TECHNICAL ADVANTAGES

Capacity: 10-170T/H

Fineness: 0.84-0.037mm

- New grinding device

- Automated electronic control system

- Drying and grinding two-in-one

Capacity: 3-60T/H

Fineness: 1.6-0.045mm

- Patented product

- Thin oil lubrication system

- Energy saving, environmentally friendly

Capacity: 3-15T/H

Fineness: 325-2500mesh

- Higher yield and better quality

- Multi-head powder selection,more economical

- Safe and reliable,stable operation

Capacity: 500-25000KGPH

Fineness: 325-3250mesh

- Stable, reliable, environmentally friendly

- High efficiency and low loss

- High fineness

CUSTOMER CASES

PURSUING THE ZENITH TECHNOLOGY AND QUALITY

Shanghai Zenith Machinery Co., Ltd. is a hi-tech enterprise specializing in the

research, development and production of industrial powder grinding equipment.

We focus on the needs of customers in different fields, and our product processing range covers 1-3mm

coarse powder, 20-400mesh fine powder, 400-1250mesh ultrafine powder and 1250-3250 mesh micro powder.

Our equipment have got ISO international quality system certification, European Union CE certification

and Customs Union CU-TR certification.

At present, our service network has covered more than 180 countries and regions in Asia, Africa, Europe,

America and Oceania, and established overseas offices in more than 30 countries.

Get Solution & Price Right Now!

If you would like to receive personalized solutions and a free quote, kindly provide your information below.