INTRODUCTION OF LITHIUM SPODUMENE

Lithium spodumene is the primary mineral source for the lithium industry and is a characteristic mineral found in lithium-rich granitic pegmatites. It mainly forms in granitic pegmatite veins. Unlike other pyroxene group minerals, lithium spodumene is a pegmatitic mineral and is often associated with quartz, tourmaline, beryl, and other minerals.

As a provider of comprehensive grinding equipment solutions, Zenith has been committed to developing more efficient, energy-saving, and environmentally friendly grinding equipment of lithium spodumene,such as LM vertical mill,MTW European trapezium mill,XZM ultrafine mill,LUM ultrafine vertical mill and etc.

INDUSTRIAL APPLICATIONS OF LITHIUM SPODUMENE

-

Lithium-ion Battery

-

Glass Industry

-

Ceramics Industry

-

Metallurgical Industry

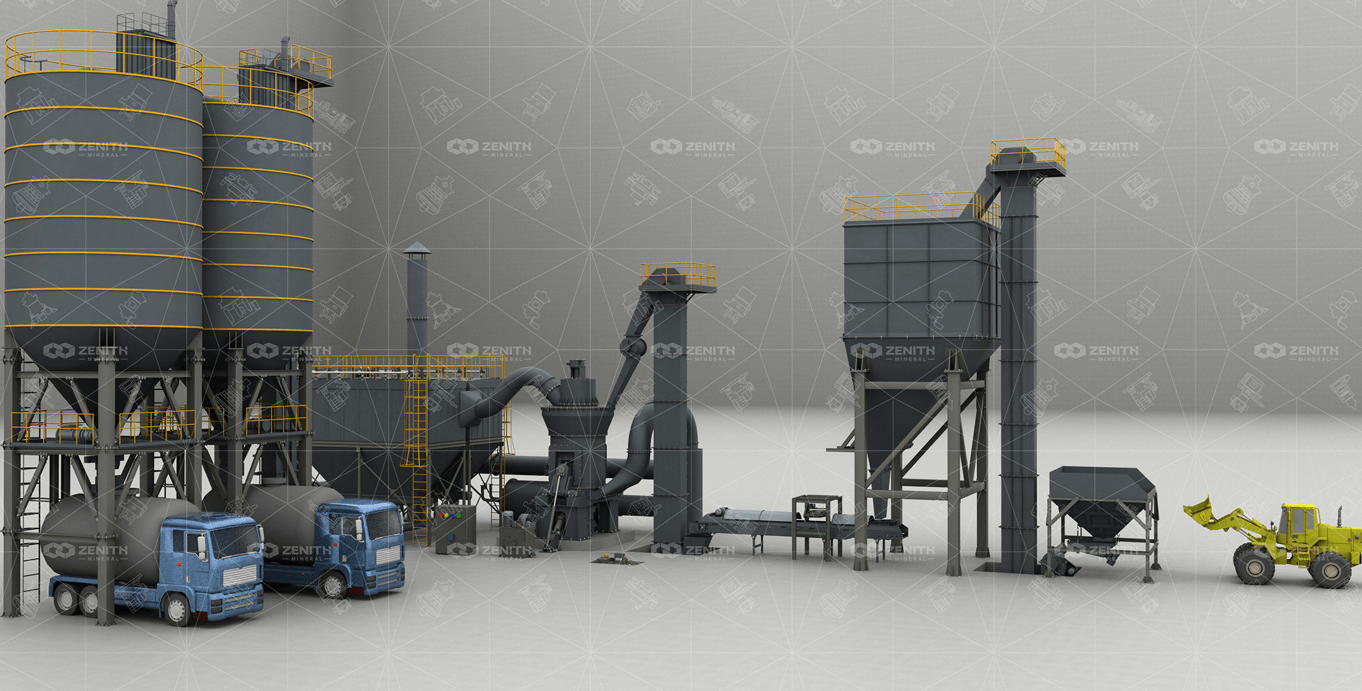

INTEGRATED SOLUTION FOR DEEP PROCESSING OF LITHIUM SPODUMENE

In the context of the current transformation and upgrading of the energy industry, the lithium battery new energy industry is rapidly emerging. Among these, lithium carbonate, as an important raw material for lithium battery electrode materials, is experiencing a continuous increase in demand. Against this backdrop, the research on the process of extracting lithium carbonate from spodumene has become particularly important.

The process of producing lithium carbonate from spodumene primarily includes steps such as crushing and grinding of spodumene or lepidolite, leaching, crystallization, and drying. Among these, crushing and grinding is the first step in the process of producing lithium carbonate from spodumene and is a critical link that determines the quality of the lithium carbonate product.

-

1

Spodumene concentrate

-

2

β-transformation roasting

-

3

LM vertical mill

-

4

Acidification roasting

-

5

Leaching

-

6

Precipitation and impurity removal

-

7

Evaporation concentration

-

8

Lithium precipitation

-

9

Lithium carbonate

Sulfuric acid roasting process flow chart

SELECTION OF GRINDING EQUIPMENT

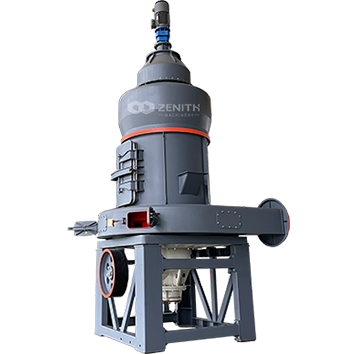

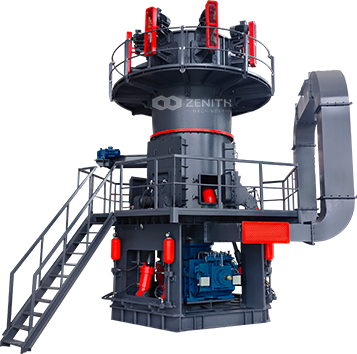

LM Vertical Roller Mill

LM Vertical Roller Mill is a specialized equipment designed for the preparation of key materials in the new energy industry. It is a large, efficient, and energy-saving grinding product developed by Shanghai Zenith through the comprehensive introduction of advanced technologies from Germany, such as Loesche and Pfeiffer, combined with our company's nearly 40 years of research and manufacturing experience. This equipment integrates crushing, drying, grinding, classification, and conveying into one unit, and possesses multiple independent patented technologies and intellectual property rights, with its main technical and economic indicators reaching an internationally advanced level.

High grinding efficiency and large output

Low energy consumption and low wear

Small footprint and low investment

Intelligent control for easy operation

High drying efficiency and automatic slag discharge

Low-carbon and environmentally friendly operation under negative pressure

HOT-SELLING EQUIPMENT

-

MTW European Trapezium Mill

Fineness: 1.6-0.045mm

-

LUM Ultrafine Vertical Mill

Fineness: 325-2500mesh

-

XZM Ultrafine Grinding Mill

Fineness: 325-3250mesh

CASES OF LITHIUM SPODUMENE GRINDING LINE

-

20,000 tons/year of roasted spodumene grinding

Feed size: ≤ 35mm

Product size: 250-350 mesh

Capacity: 20,000 tons/year

Equipment: LM Vertical Roller Mill -

80,000 tons/year of lithium carbonate grinding

Feed size: ≤ 50mm

Product size: 200-300 mesh

Capacity: 80,000 tons/year

Equipment: MTW European Version Trapezium Grinding Mill

Shanghai Zenith Machinery Co., Ltd. is a hi-tech enterprise specializing in the research, development and production of industrial powder grinding equipment.

We focus on the needs of customers in different fields, and our product processing range covers 1-3mm coarse powder, 20-400mesh fine powder, 400-1250mesh ultrafine powder and 1250-3250 mesh micro powder. Our equipment have got ISO international quality system certification, European Union CE certification and Customs Union CU-TR certification.

At present, our service network has covered more than 180 countries and regions in Asia, Africa, Europe, America and Oceania, and established overseas offices in more than 30 countries.

Get Solution & Price Right Now!

If you would like to receive personalized solutions and a free quote, kindly provide your information below.