Pre grinding has achieved significant new achievements in the industrial field, especially in the cement industry. Here is a detailed summary of these new achievements:

1.Technological Innovation and Application

Research and development of efficient pre grinding equipment:

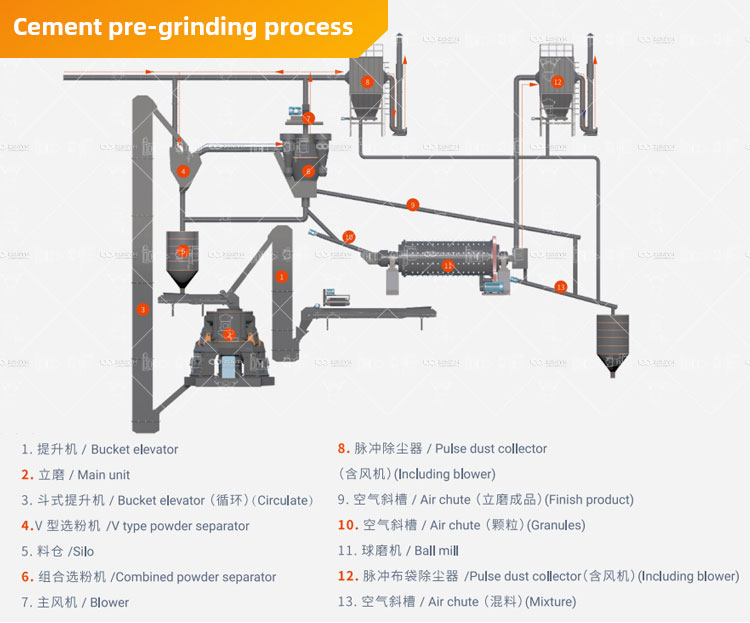

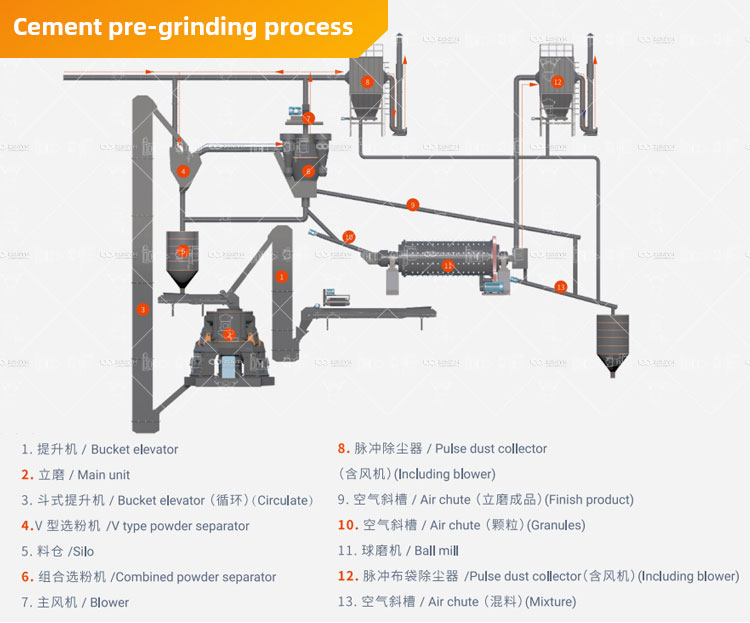

Roller press and external circulation pre grinding vertical mill: These two devices have been widely used in cement combined (semi final) grinding systems, significantly improving the processing capacity of the pre grinding section and the overall energy-saving effect of the system. The roller press greatly reduces the particle size of the material through high-pressure extrusion, providing good conditions for the subsequent grinding and shaping of the tube mill. The external circulation pre grinding vertical mill achieves efficient pre grinding by implementing cyclic rolling of materials through multiple high-pressure grinding rollers.

SPC control system: The SPC control system used for the roller press ensures that the roller press maintains stable and high working pressure, improves the extrusion work capacity, and is conducive to efficient and low consumption operation of the system.

Improvement of grading technology:

With the rapid development of material classifier technology and equipment manufacturing technology, various forms of classifiers have been introduced and applied in the pre grinding section, further improving the output and energy-saving effect of cement grinding systems.

2.Energy conservation, emission reduction and green development

Energy consumption reduction:

The application of efficient pre grinding technology has significantly reduced the power consumption of cement grinding systems. At present, most cement grinding systems in China's cement industry have been equipped with high-efficiency material bed pre grinding technology equipment, and various low-energy equipment and technology combinations have been adopted, achieving a significant reduction in energy consumption.

According to the latest national standard GB/T16780 "Energy Consumption Limits for Cement Unit Products", the power consumption level of the cement grinding section is divided into three levels, with the first level quota indicator being ≤ 26 kWh/t, reflecting strict requirements for energy conservation and emission reduction.

The development of green building materials:

Pre grinding technology not only improves production efficiency, but also promotes the development of green building materials. By reducing energy consumption and emissions, the cement industry has taken a solid step on the path of green development.

You can specifically understand the process flow of cement pre grinding:

3.Market promotion and economic benefits

Increased market acceptance:

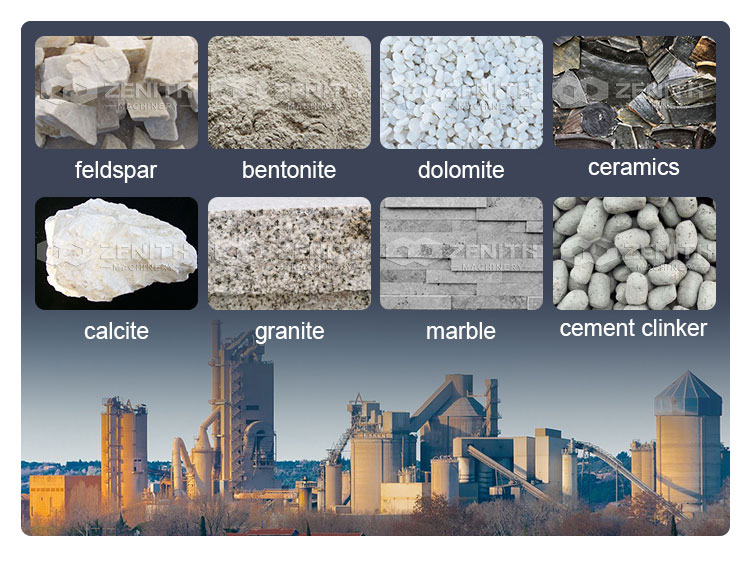

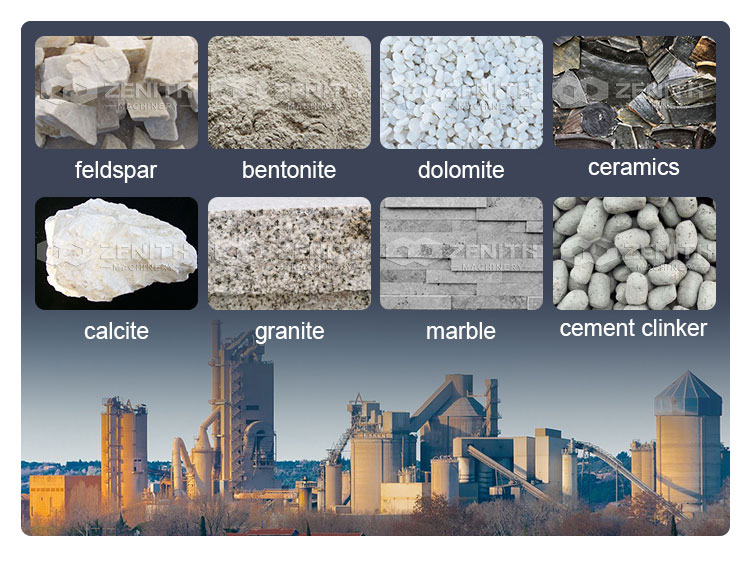

Pre grinding is widely used in the processing and grinding of raw materials such as feldspar, bentonite, dolomite, ceramics, calcite, granite, marble, etc., especially playing an important role in the field of cement clinker.With the continuous maturity and significant application effects of pre grinding technology, more and more cement enterprises are beginning to accept and adopt this technology. The demand for efficient, energy-saving, and environmentally friendly pre grinding equipment in the market is increasing day by day.

Significant economic benefits:

Cement enterprises that adopt pre grinding technology have achieved significant economic benefits while reducing production costs and improving production efficiency. The application of pre grinding technology has brought more profit margins and development momentum to enterprises.

4.Policy Support and Future Development

Policy promotion:

At the national level, a series of industrial energy conservation and carbon reduction policies have been introduced to encourage and support enterprises to adopt high-efficiency energy-saving technologies. Pre grinding technology, as one of the important means of energy conservation and carbon reduction in the cement industry, has received strong policy promotion.

Future prospects:

With the continuous advancement of technology and changes in market demand, pre grinding technology will be widely applied and developed in the cement industry and other industrial fields. In the future, pre grinding technology will pay more attention to the development direction of intelligence, automation, and greening, contributing more to the sustainable development of the industrial field.

In summary, pre grinding has achieved significant new achievements in the industrial field, especially in the cement industry. It not only improves production efficiency, reduces energy consumption and emissions, but also promotes the development of green building materials and the improvement of enterprise economic benefits. With the continuous advancement of technology and the continuous promotion of policies, pre grinding technology will usher in a broader development prospect.