With the rapid development of industries such as plastics, coatings, rubber, and papermaking, the market demand for calcite micro powder is moving towards a new height of "ultra refinement and high purification". Downstream customers have increasingly stringent requirements for powder fineness, purity, and stability, and traditional processing equipment is unable to meet the efficient and precise production needs. Shanghai Zenith Grinding Equipment Company has a keen insight into market trends and relies on its independently developed XZM ultrafine powder ultrafine grinding mill to provide breakthrough tools for calcite processing enterprises, helping customers achieve a dual leap in production and profit.

Three core advantages of ultrafine grinding mill

Breakthrough in production capacity, doubling efficiency

By adopting innovative grinding structures and intelligent grading systems, the single machine production capacity has increased by 40% -60% compared to traditional equipment, and the daily output of finished products has easily exceeded the industry average level.

The order that used to require 3 production lines can now be completed with 2 XZM ultrafine grinding mills! "- commented by a production supervisor of a cooperative customer.

Precision and controllability of fineness, comprehensive upgrade of quality

Through multi-level grinding chambers and dynamic adjustment technology, the fineness of calcite products can be stably controlled within the range of 3-45 μ m. The proportion of D97 ≤ 5 μ m ultrafine powder exceeds 90%, with a purity of over 99.2%, directly meeting the raw material standards for high-end products.

After testing, the customer added an order on the spot and said that the quality of our powder far exceeded expectations! "- Customer feedback record.

Low consumption and environmental protection, cost optimization

The overall energy consumption of the machine has been reduced by 35% compared to similar products, equipped with pulse dust removal and circulating water cooling systems, resulting in a cleaner production environment, further compression of operation and maintenance costs, and an overall profit margin increase of 20% -35%.

Customer Witness: From Equipment Upgrade to Profit Transformation

After a certain calcite processing enterprise in Jiangsu introduced ultrafine grinding mill, the production line efficiency increased by 55%, and the finished product qualification rate jumped from 82% to 98%, successfully entering the high-end plastic filler market. The single ton profit increased by more than 400 yuan, and the expected return on investment was achieved in just 8 months.

The XZM micro powder grinding mill from Zenith is not only a device, but also the 'golden key' for us to open up the high-end market.

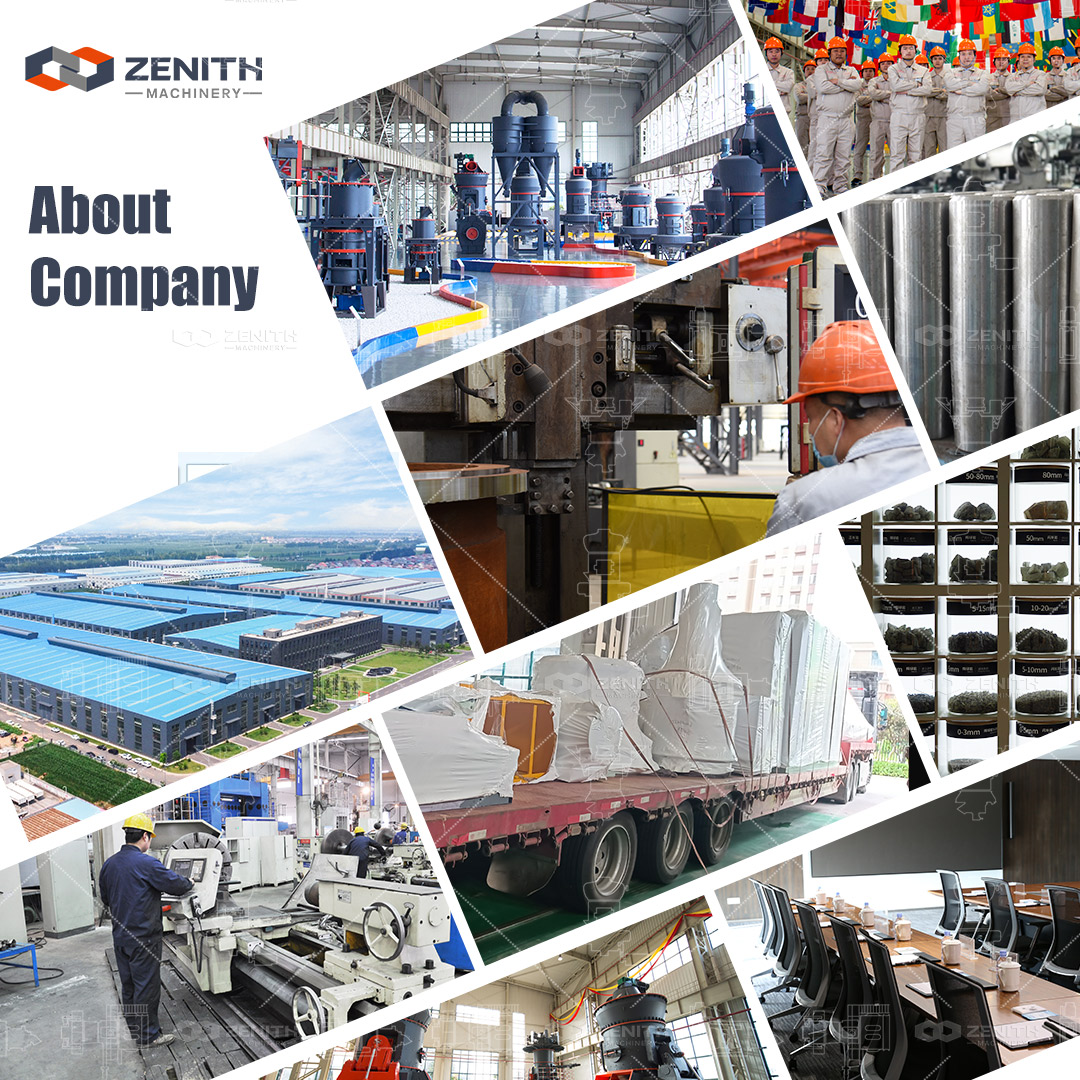

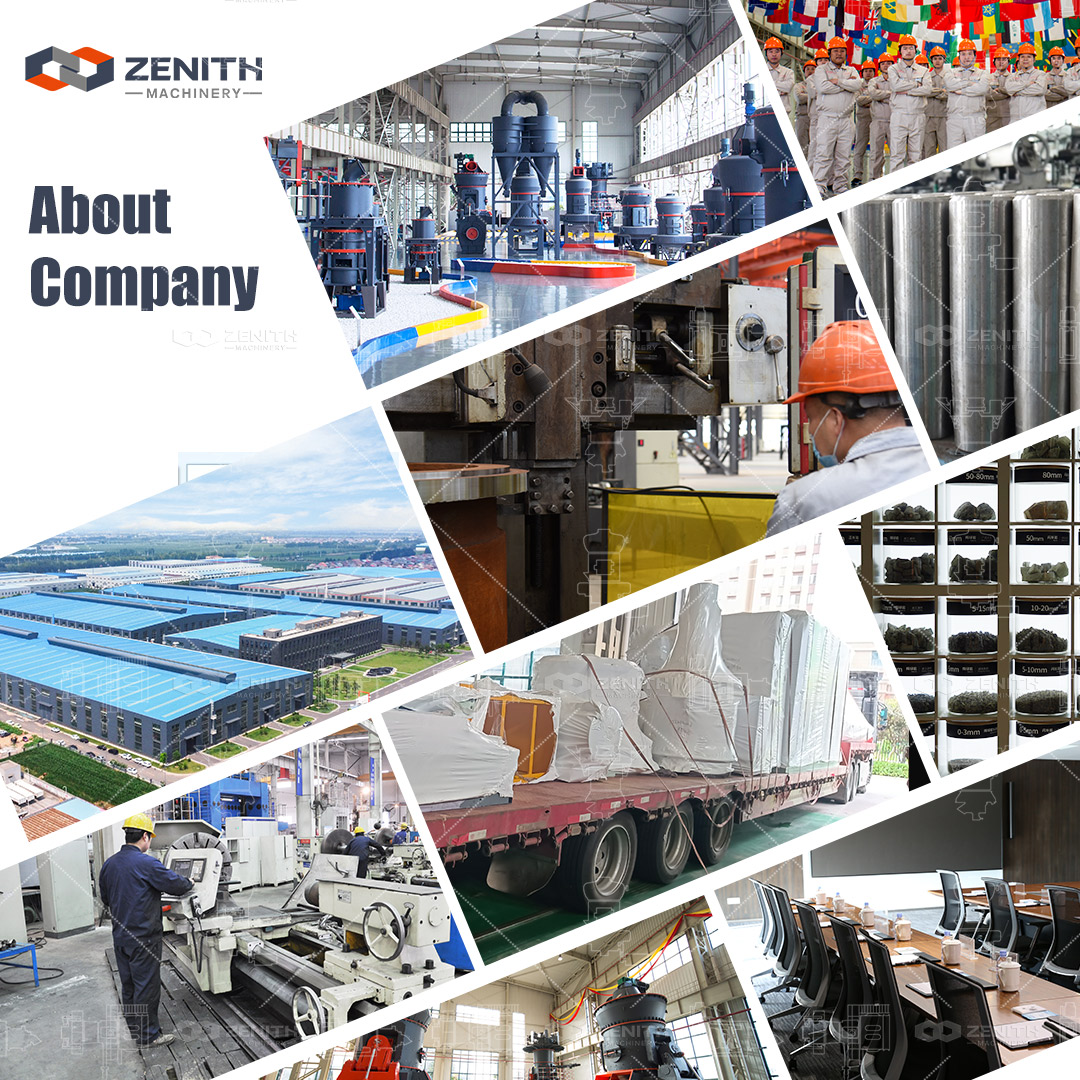

Shanghai Zenith Grinding Equipment Company has always adhered to the concept of "precision grinding, value symbiosis" and continues to invest in research and development innovation. The XZM series ultrafine ultrafine grinding mill is suitable for processing various non-metallic minerals such as calcium carbonate, talc, and wollastonite. The company can provide full process process process design, equipment installation and commissioning, and lifelong maintenance services to help partners seize the opportunity in the ultrafine powder field.

With the rapid development of industries such as plastics, coatings, rubber, and papermaking, the market demand for calcite micro powder is moving towards a new height of "ultra refinement and high purification". Downstream customers have increasingly stringent requirements for powder fineness, purity, and stability, and traditional processing equipment is unable to meet the efficient and precise production needs. Shanghai Zenith Grinding Equipment Company has a keen insight into market trends and relies on its independently developed XZM ultrafine powder ultrafine grinding mill to provide breakthrough tools for calcite processing enterprises, helping customers achieve a dual leap in production and profit.

With the rapid development of industries such as plastics, coatings, rubber, and papermaking, the market demand for calcite micro powder is moving towards a new height of "ultra refinement and high purification". Downstream customers have increasingly stringent requirements for powder fineness, purity, and stability, and traditional processing equipment is unable to meet the efficient and precise production needs. Shanghai Zenith Grinding Equipment Company has a keen insight into market trends and relies on its independently developed XZM ultrafine powder ultrafine grinding mill to provide breakthrough tools for calcite processing enterprises, helping customers achieve a dual leap in production and profit. Three core advantages of ultrafine grinding mill

Three core advantages of ultrafine grinding mill Shanghai Zenith Grinding Equipment Company has always adhered to the concept of "precision grinding, value symbiosis" and continues to invest in research and development innovation. The XZM series ultrafine ultrafine grinding mill is suitable for processing various non-metallic minerals such as calcium carbonate, talc, and wollastonite. The company can provide full process process process design, equipment installation and commissioning, and lifelong maintenance services to help partners seize the opportunity in the ultrafine powder field.

Shanghai Zenith Grinding Equipment Company has always adhered to the concept of "precision grinding, value symbiosis" and continues to invest in research and development innovation. The XZM series ultrafine ultrafine grinding mill is suitable for processing various non-metallic minerals such as calcium carbonate, talc, and wollastonite. The company can provide full process process process design, equipment installation and commissioning, and lifelong maintenance services to help partners seize the opportunity in the ultrafine powder field.