In today's diversified industrial production sector, limestone powder has become an indispensable basic raw material for many industries due to its unique advantages. From an environmental perspective, limestone powder is completely free of harmful substances such as formaldehyde and benzene, aligning with the concept of green production. In terms of resources, limestone is abundant and has a low acquisition cost, making limestone powder economically advantageous. It can effectively reduce production costs for enterprises, demonstrating strong industrial support.

Project Overview

India's abundant limestone mineral resources provide a unique advantage for the development of this enterprise. Leveraging this regional advantage, the company has established an intelligent and efficient limestone grinding production line, with its product quality highly recognized in the market.

In the layout of the grinding production line, Shanghai Zenith MTW European Trapezium Grinding Mill has become the core "contributor." The equipment operates with exceptional stability, continuously producing high-quality powdered products with high capacity and low energy consumption, significantly enhancing overall production efficiency. Moreover, the production site maintains a clean and tidy working environment, ensuring that efficiency and environmental protection go hand in hand, providing strong support for the user enterprise in achieving green industrial aesthetics.

On-Site Coverage

Two Sets of Shanghai Zenith MTW European Trapezium Grinding Mill

Clean and Tidy Factory Environment

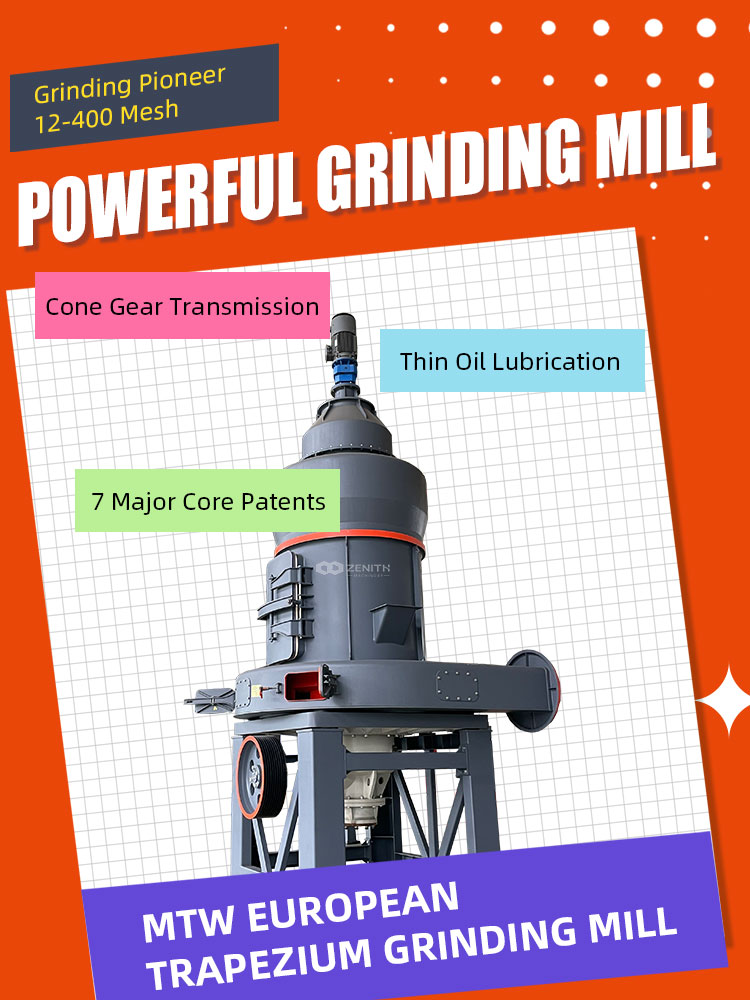

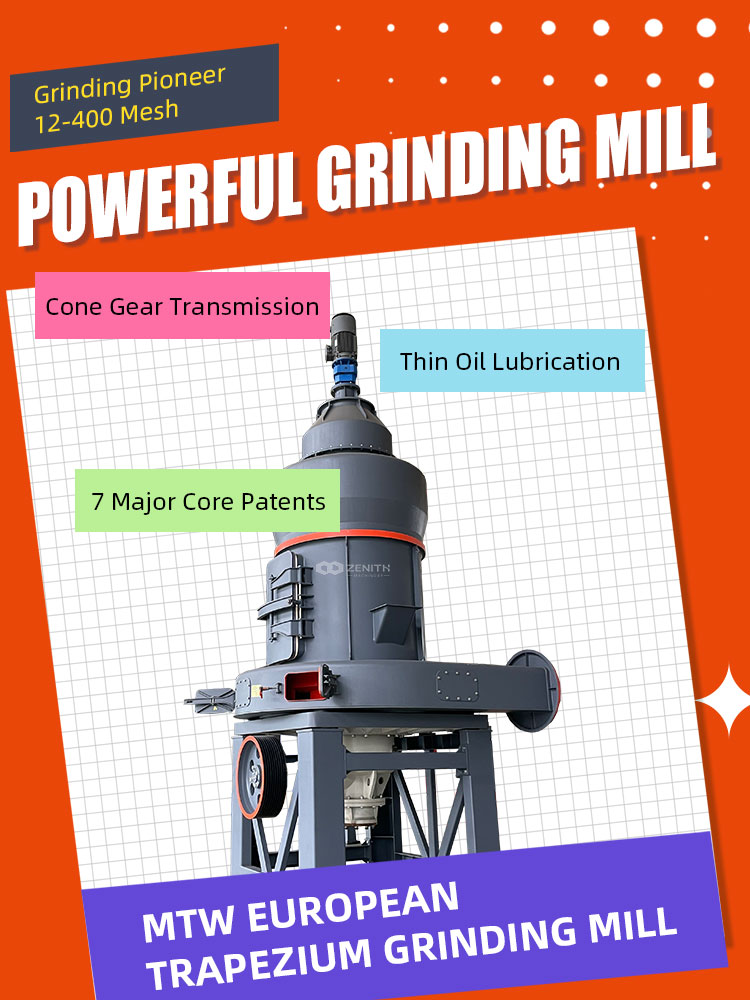

Star Product

1.Technologically Advanced

National Patent Product, Seven Generations of Mill Upgrades and 2.Transformations, Mature and Stable.

Not Prone to Clogging, High Powder Selection Efficiency

The use of a curved arc-shaped air duct, with internal outlet directions conducive to material dispersion, minimizes the risk of clogging. A new type of hanging cage classifier with variable frequency control allows for adjustable and controllable product fineness, significantly improving powder selection efficiency.

3.Advanced Transmission, Stable Operation

The cone gear transmission is integrated, providing strong power, high efficiency, large output, and low energy consumption. The sunken design ensures smooth operation with minimal vibration and low noise.

4.The spindle drive system and fan drive system both use thin oil lubrication, resulting in long oil change intervals and reduced maintenance frequency, leading to lower operating costs.

5.Economical Investment, Green and Environmentally Friendly

The system occupies a small area, has a simple structural layout, strong integration, low infrastructure costs, a short construction period, and quick capital recovery. The final product has low pollution and high whiteness. The entire system operates under negative pressure, preventing dust leakage and meeting the latest environmental protection requirements.

6.Integrated Solution

Provides a comprehensive integrated solution that includes design, supply, construction, and service, ensuring peace of mind and confidence!

Process Flow

Limestone raw materials are uniformly and continuously fed into the main grinding chamber by a variable frequency belt feeder. The ground material is then carried by the airflow from the fan to the classifier. Under the action of the analyzer, materials that do not meet the fineness requirements fall back into the grinding chamber for regrinding, while qualified materials are transported through pipes with the airflow into the cyclone collector for separation and collection. The finished powder is discharged through the discharge device. The separated airflow returns to the fan through the upper return air duct of the cyclone collector. This production system operates under negative pressure and closed conditions, equipped with a pulse dust collector to prevent dust overflow, complying with national environmental protection standards.

On-Site Coverage

On-Site Coverage