Coal gangue is a type of solid waste generated during the mining and washing of coal. It is mainly composed of a mixture of rock, coal particles, and other minerals. Its appearance is typically black or gray and has a blocky shape, with high hardness and density.

The utilization of coal gangue is of significant importance. From an environmental perspective, the large accumulation of coal gangue occupies land resources and may pollute the soil, water, and air. Effective utilization can reduce environmental pollution and improve the ecosystem. From a resource perspective, coal gangue contains a certain amount of carbon and other useful minerals, which can be extracted and utilized through technological means, transforming waste into resources, increasing resource utilization efficiency, and alleviating the pressure of resource scarcity.

Project Overview

This project is focused on the processing and powder production of coal gangue. The user company specializes in innovative resource utilization and is deeply researching cutting-edge technologies and processes for coal gangue processing. Relying on an advanced R&D team and rich industry experience, the company is committed to transforming what was once considered waste into valuable resources. Through a series of refined processing steps, the efficient utilization of coal gangue is achieved, effectively reducing environmental pollution caused by the accumulation of coal gangue. Additionally, it provides the market with a diverse range of high-quality products. The produced kaolin products are widely used in fields such as coatings, wires and cables, and high-end fiberglass, promoting the vigorous development of the comprehensive resource utilization industry and contributing significantly to the circular economy.

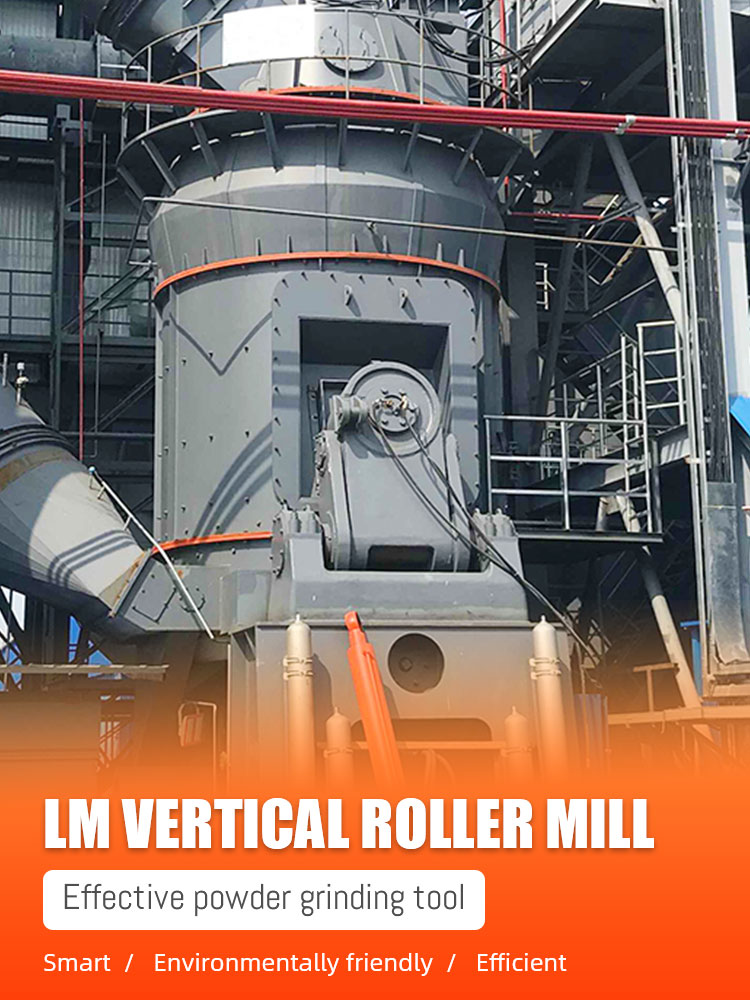

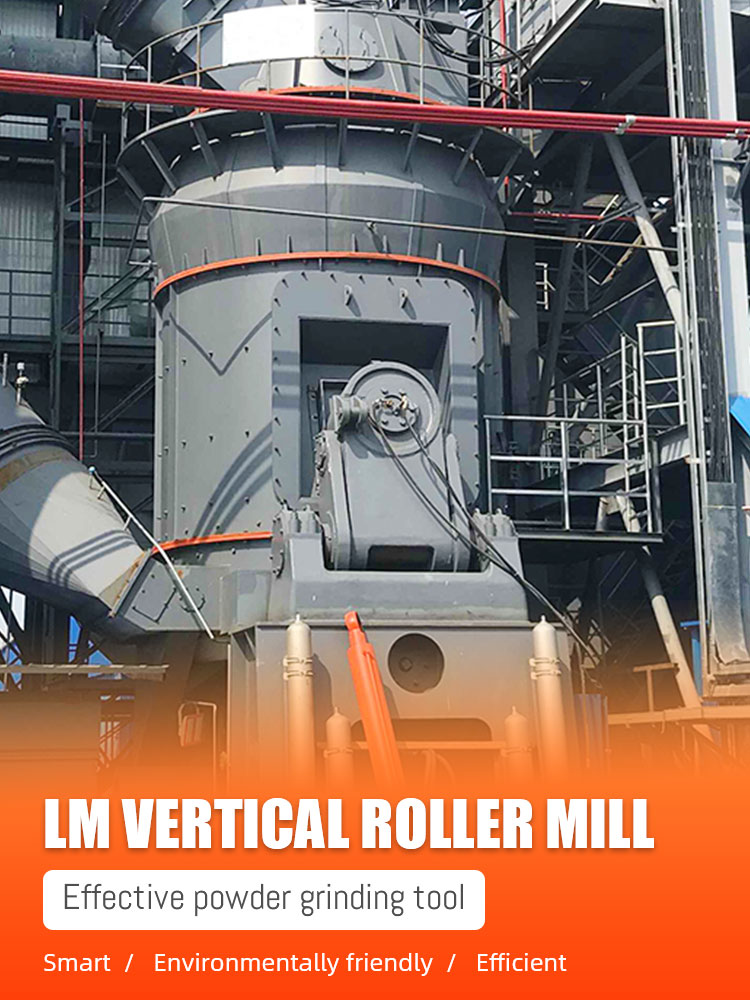

After comprehensive and detailed investigations from multiple angles in the early stages of the project, the user ultimately chose to adopt the Shanghai Zenith LM series vertical mill. The entire production line for this project is built by Shanghai Zenith, featuring a rational design of the production site, a compact layout, low carbon and environmentally friendly production, and high operational efficiency!

Material: Coal Gangue (Coal Series Kaolin)

Equipment: Shanghai Zenith LM Vertical Mill

On-site Equipment Selection and Technical Advantages

Equipment Selection

Shanghai Zenith LM Vertical Roller Mill integrates grinding, drying, classification, and transportation. It meets the high standards required for limestone milling, achieving not only high product purity and precise particle size control but also energy savings and high levels of automation, allowing for continuous and stable production 24 hours a day. Users can make diversified selections based on their requirements for output, fineness, and investment.

Technical Advantages

Part 1: Technologically Advanced with Low Investment Costs

Integrating crushing, grinding, drying, classification, and transportation into one system, the layout is compact and can be arranged outdoors, significantly reducing investment costs.

Part 2: High Grinding Efficiency and Good Product Quality

The special design of the grinding roller and grinding plate structure ensures high grinding efficiency; the finished product has a uniform particle size distribution and good quality.

Part 3: Reliable Quality and Stable Operation

The grinding roller is equipped with a limit device to prevent direct contact between the grinding roller and the grinding plate, resulting in low vibration. It also features an automatic slag discharge function to ensure the safe operation of the equipment.

Part 4: Large Drying Capacity and Wide Adaptability

It can use hot air to transport materials, drying materials with moisture content as high as 15% before grinding, with the moisture content after grinding being less than 1%, allowing for a wide range of applications.

Part 5: High Level of Automation

Equipped with an automatic control system, it allows for remote operation, interlocking protection, reliable performance, and easy operation.

Part 6: Easy Maintenance and Low Operating Costs

The grinding roller uses forced thin oil lubrication and is equipped with a hydraulic roller turning device, allowing the grinding roller to be turned out of the machine for maintenance without disassembly, making it convenient and quick.